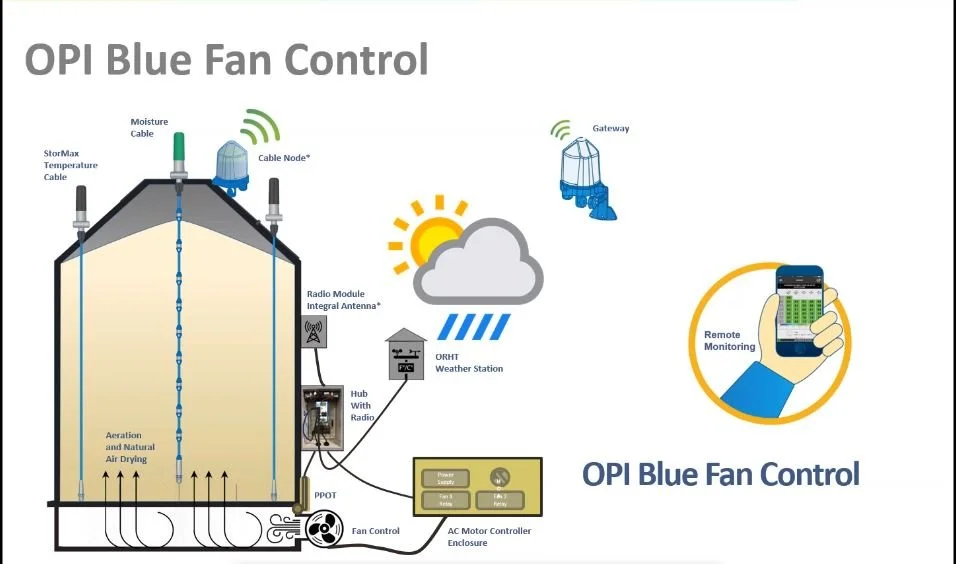

OPI Blue Fan Control

Automated Fan Control

OPI Blue and Integris solutions enable you to automate the operation of your grain conditioning systems to maximize the value of your stored assets. In addition to optimizing quality and moisture content, you will be able to minimize costs through electrical, fumigation and labour savings. And with more confidence, you can also turn your storage into a profit centre by being paid carry to store longer.

Alarms & Fan Controls

Prevent grain spoilage with an on-screen, audio, visual, text message or e-mail alarm notifications that are sent directly to your desktop or wireless device. Receive ongoing software updates and help desk access with options for extended warranty and annual site maintenance.

Automate your grain conditioning

What is Grain Conditioning?

Grain conditioning increases the storage life of grain and minimizes grain spoilage and quality loss. The primary conditioning operations are in-bin natural drying of grain to reduce the grain moisture, followed by aeration to cool the grain. Sometimes over-dried grain can also be rehydrated to acceptable moisture levels to minimize shrink loss.

In-Bin Natural Air Drying

Grain bins equipped with a proper aeration system can be successfully used to dry grain using natural air and a little supplemental heat (optional). Natural air in-bin drying is the highest quality and most energy-efficient process. Appropriate and automated fan control strategies are required to optimize the drying performance with uniform drying, energy efficiency and minimum under/over-drying.

Grain Aeration

Grain aeration lowers grain temperature to increase safe storability and protection against mould and insects. Once the grain has reached target drying it must be cooled as soon as possible, and should be uniformly cooled to 1.7-4.4°C or 35-40°F for winter holding. Do not freeze the grain as it may result in significant condensation in the following spring/summer.

Grain Rehydration

At times, crops such as soybeans and canola arrive from the fields at 2-3% below the maximum acceptable straight grade moisture levels. Physically adding water to the grain is illegal and considered adulteration. However, moisture can be legally added by blowing natural humid air through the grain silo.

Dryeration

Dryeration is the process of high-temperature grain drying and subsequent cooling (aeration). In dryeration, grain from a high-temperature dryer is removed with 2-3% higher moisture than desired for safe storage levels and placed in tempering (also referred to as heat soaking, steeping, and steaming) bins and then slowly aerated/cooled.

Natural Air

The amount of water vapor in the air is determined by the combination of temperature and relative humidity. Since warm air can hold more water vapor when it is cooled and humidified in the drying process, it is preferred for drying.

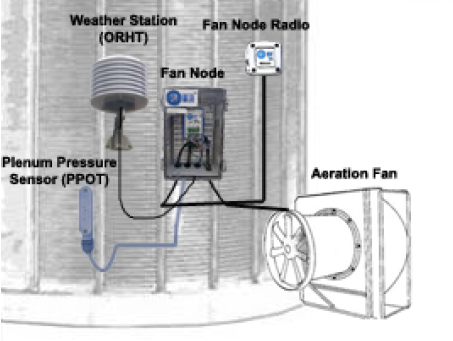

OPI Fan Control Components